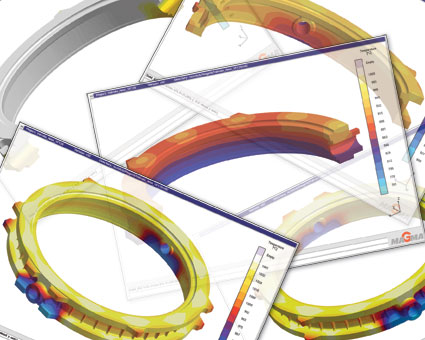

MAGMASOFT CENTRIFUGAL CASTING SOFTWARE

Software Features: model building, mold filling, solidification and CAD interfaces. Calculations are performed using the finite difference method and combine both a thermal and volumetric approach to predicting casting problems. As we strive to attain just-in-time deliveries and simultaneous engineering, process modeling becomes an indispensable tool.Īmerican Foundrymen's Society 505 State Street Des Plaines, Illinois 60016-8399 847/824-0181, fax 847/824-7848, īackground: The 3D system is a PC-based package that combines speed, accuracy, ease of use and low cost. Process modeling then becomes a valuable communication tool between the foundry and the original equipment manufacturer (OEM). If more parts that are ultimately made by the casting process were designed with metalcasting in mind, overall part quality could be improved dramatically, and manufacturing costs would decrease. The 1-F Committee has spent considerable time introducing the benefits of process modeling to the casting design community as well as to foundries. Contact information is provided for each package to assist foundries seeking additional information.

The format was designed to concisely state the major features and capabilities of each package. Because software is in continuous change, the AFS Process Modeling and Design Committee (1-F) prepared the following updated list of process modeling software from the responses to a recent committee survey. Three years ago, modern casting (July 1994) published an article on evaluating process modeling software. Many published sources quantify the savings derived from process modeling. Another article written by Sivyer Steel in that issue shared how the foundry saved an estimated $530,000 over three years in reduction of scrap and rework and manufacturing costs. Across the board, they reported a 40%-plus reduction in lead and production times, 30% reduction in labor and rework costs and a 25% improvement in yield. In a project conducted by the American Metalcasting Consortium (modern casting, September 1996), users were surveyed about the costs and benefits of using process modeling software. Today, this technology is being further embraced by the metalcasting industry simply because of the tremendous benefits that come from making a part right - the first time. Since the introduction of this technology in the mid-1980s, the accuracy, speed and usefulness of these packages have improved dramatically. Essentially, such modeling is a tool for foundrymen to determine whether a quality casting will be produced. This type of modeling simulates from the beginning of the pour through shakeout, although some packages may offer additional processes such as heat treatment. As the benefits of these packages became known, more foundries began investing in this technology.Īs both personal computer (PC) and workstation computers grew in power and fell in price, one type of software moved to the forefront of technical development - process modeling. The first AFS CompuCast Conference was held in 1983, and introduced foundries to the different types of emerging software. Over the past 15 years or so, the technical use of computers in foundries has steadily increased. Here's an updated survey of available packages. APA style: Sources of casting modeling software: solidification modeling is providing unprecedented benefits to foundries and OEM designers.Here's an updated survey of available packages." Retrieved from Sources of casting modeling software: solidification modeling is providing unprecedented benefits to foundries and OEM designers.

MAGMASOFT CENTRIFUGAL CASTING FREE

Here's an updated survey of available packages." The Free Library.

0 kommentar(er)

0 kommentar(er)